HEAT TRANSFER & FLUID SYSTEMS

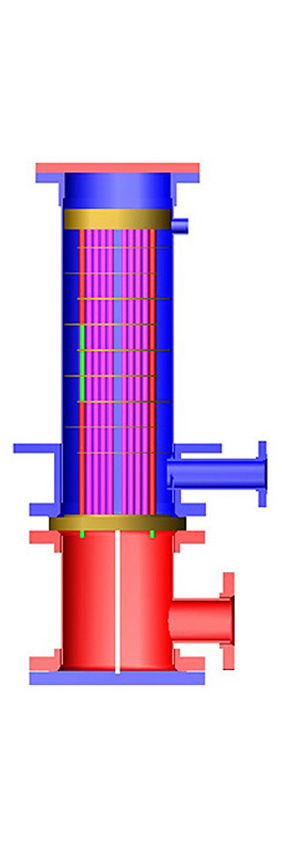

Embedded Process Design; Shell and Tube Heat Exchangers

Heat Transfer Design Engineers

page 2 of 2

Embedded Process Design; Shell and Tube Heat Exchangers

Heat Transfer Design Engineers

page 2 of 2

Art & Science

That said, the calculation of heat exchangers characterises the iterative nature of Engineering Design very well. As remarked by the (unattributed) introduction to the topic in Perry & Chilton: “The proper use of basic heat transfer knowledge in the design of heat transfer equipment is an art. The designer must constantly be aware of the differences between the idealized conditions under which the basic knowledge was obtained, vs. the real conditions of the mechanical expression of his design and its environment. The result must satisfy process and operational requirements (such as availability, flexibility, and maintainability) and do so economically. An important part of any design process is to consider and offset the consequences of error in the basic knowledge, or its subsequent incorporation into the design method, or in the translation of design into equipment, or in the operation of the equipment and the process. Heat exchanger design is not a highly accurate art under the best of conditions." These words of experience reflect a procedure in which the heuristics of the design process and the empiricism of scientific method are qualified with as much knowledge and understanding of the field as may be brought to bear by the practicing heat transfer design consultant.

Activities and Workscope

We handle all aspects of process heat transfer design, and are able to resolve situations in which they are either not being understood - or have been incorrectly applied. We research, design, investigate, model and create practical solutions to meet practical requirements, and have built many types of special heat exchangers for a wide application base - for example:

Presssurized-air preheater with flash steam recovery for Glaxo Smith Kline;

Re-engineering of Class 158 DMU HVAC systems for Metro-Cammell;

Heat transfer design engineers for the Siberian Oil Lake Programme;

Heat Transfer Consultants to the Design Council, PERA, and the DTI;

Shell and tube heat exchangers for IAC thermal fluid heating plant;

Large steam condensers and sugar boiling pans for Tate & Lyle;

Heat exchange equipment for National Maritime College, RoI

Variable concentration batch heating for Banner Chemicals

R-R Fuel Test Rig Thermal Systems for Cullum Detuners

Regenerative furnace design for Stein Atkinson Stordy

Heat transfer design consultant to Spooner Industries

Cylinder block tempering for Jaguar Land Rover